Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 282

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: session_set_cookie_params(): Cannot change session cookie parameters when headers already sent

Filename: Session/Session.php

Line Number: 294

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 304

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 314

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 315

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 316

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 317

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: ini_set(): Headers already sent. You cannot change the session module's ini settings at this time

Filename: Session/Session.php

Line Number: 375

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: session_set_save_handler(): Cannot change save handler when headers already sent

Filename: Session/Session.php

Line Number: 110

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

Severity: Warning

Message: session_start(): Cannot start session when headers already sent

Filename: Session/Session.php

Line Number: 143

Backtrace:

File: /home/tipco357/public_html/app/controllers/Product.php

Line: 8

Function: __construct

File: /home/tipco357/public_html/index.php

Line: 315

Function: require_once

|

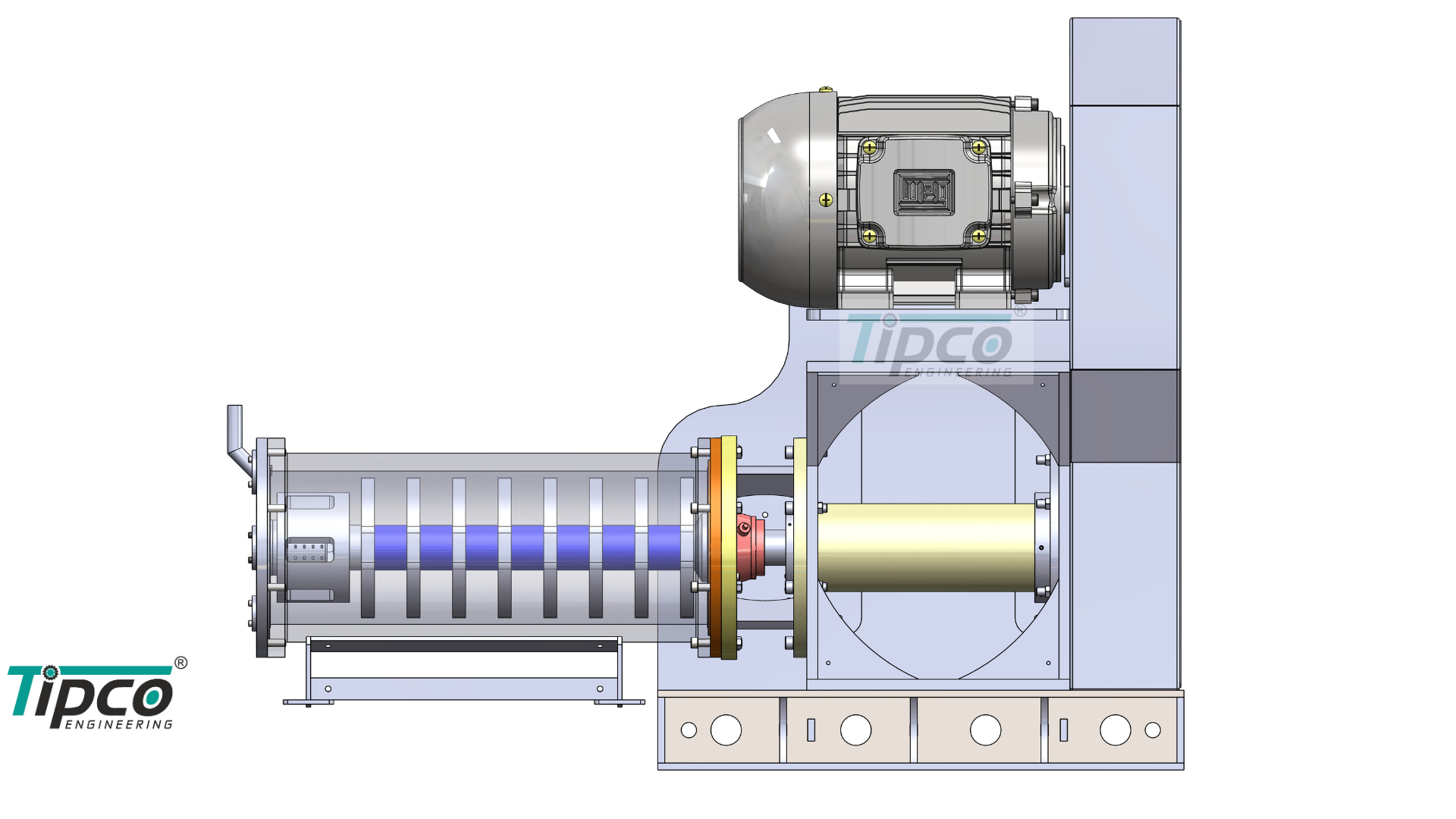

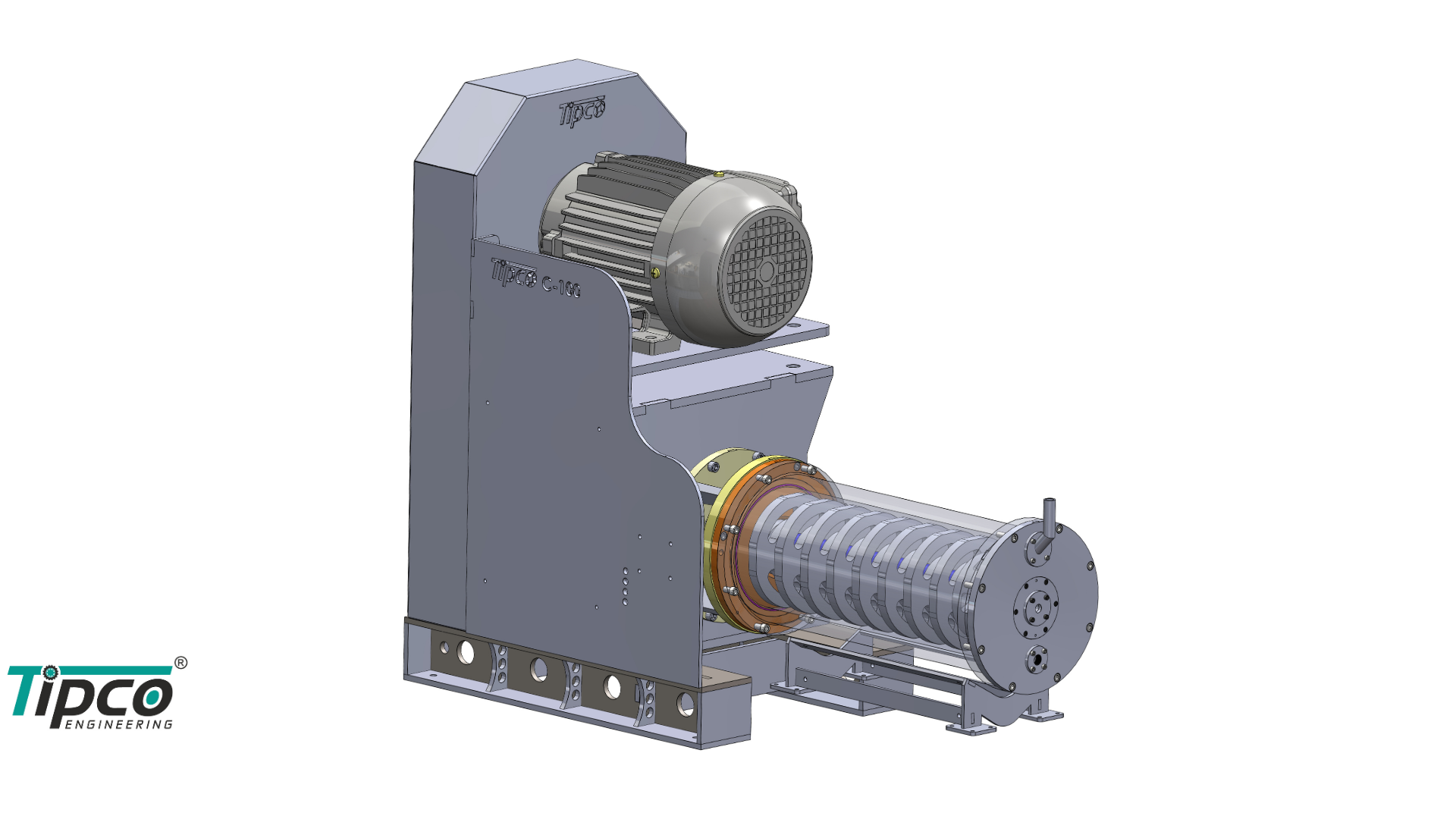

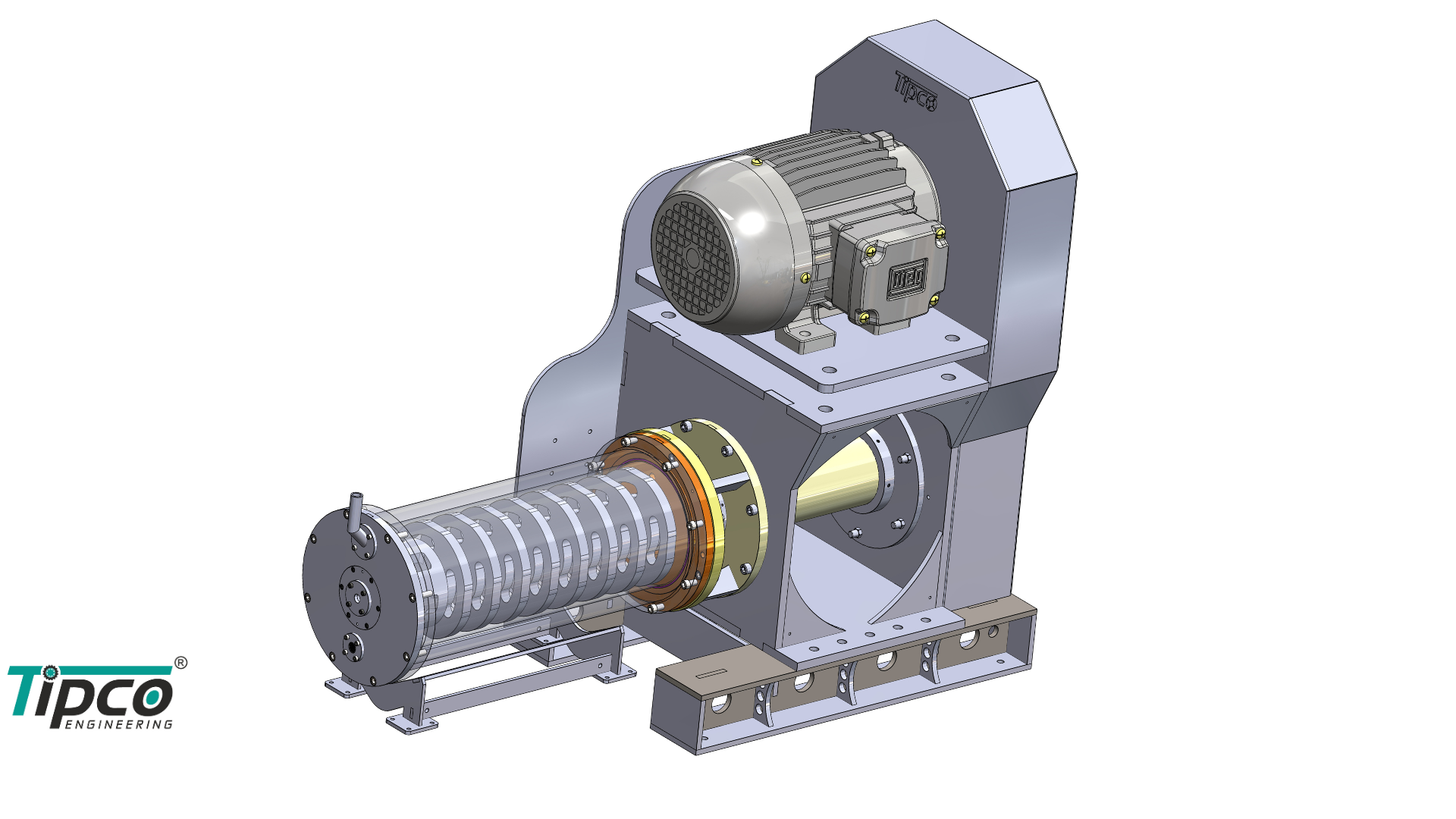

TIPCO C-Series: |

C-02 |

C-60 |

C-100 |

|

Material Output Capacity: |

4-6 Liter Per Min |

6-20 Liter Per Min |

15-35 Liter Per Min |

|

Chamber Volume: |

30 Liter |

55 Liter |

90 Liter |

|

Diameter of Beads: |

0.8 -2 mm |

0.8 -2 mm |

0.8 - 2.2 mm |

|

Disk Material Type: |

SS, TC, HCHC( High Carbon High Chromium)

|

SS, TC, HCHC( High Carbon High Chromium)

|

SS, TC, HCHC( High Carbon High Chromium)

|

|

Actual Volume of Process

Chamber: |

30 L |

50 L |

85 L |

|

Tip Speed: |

8-10 m/s |

7-12 m/s |

6-11 m/s |

|

Stator Type: |

SS, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

SS, HCHC (High Carbon High Chromium) |

|

Rotors Type: |

SS, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

|

Pins: |

Carbide |

Carbide |

Carbine |

|

Main Motor Details: |

30HP |

50HP |

60HP |

|

Weight: |

1200 kg |

1500 kg |

2200 kg |

|

Application: |

Water Based Paper Coating, Water Based Ink, Solvent

Based Paint |

Same |

Same |

|

TIPCO C-Series: |

C-02 |

C-60 |

C-100 |

|

Material Output Capacity: |

4-6 Liter Per Min |

6-20 Liter Per Min |

15-35 Liter Per Min |

|

Chamber Volume: |

30 Liter |

55 Liter |

90 Liter |

|

Diameter of Beads: |

0.8 -2 mm |

0.8 -2 mm |

0.8 - 2.2 mm |

|

Disk Material Type: |

SS, TC, HCHC( High Carbon High Chromium)

|

SS, TC, HCHC( High Carbon High Chromium)

|

SS, TC, HCHC( High Carbon High Chromium)

|

|

Actual Volume of Process

Chamber: |

30 L |

50 L |

85 L |

|

Tip Speed: |

8-10 m/s |

7-12 m/s |

6-11 m/s |

|

Stator Type: |

SS, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

SS, HCHC (High Carbon High Chromium) |

|

Rotors Type: |

SS, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

SS, TC, HCHC (High Carbon High Chromium) |

|

Pins: |

Carbide |

Carbide |

Carbine |

|

Main Motor Details: |

30HP |

50HP |

60HP |

|

Weight: |

1200 kg |

1500 kg |

2200 kg |

|

Application: |

Water Based Paper Coating, Water Based Ink, Solvent

Based Paint |

Same |

Same |

We provide best solution for your business